company insight sponsored by Titomic

Melbourne, Australia

Australian advanced manufacturing company Titomic has delivered the largest titanium, unmanned aerial vehicle, or UAV.

Titanium, with its superior strength-to-weight ratio, provides the UAV with a strong, lightweight, ruggedised design and ballistics protection, which will provide durability for reliable in-field use by military and law enforcement and is well-suited for deployment in live combat situations. As titanium’s use is often prohibitively expensive and difficult to fabricate using traditional methods, the prototype demonstrates Titomic’s ability to utilise high-performance materials, including titanium, in applications that previously did not overcome a manufacture cost-benefit analysis, forcing manufacturers to use lesser desired materials in design, such as heavier metals or fragile plastics.

The technology is widely applicable to the defence industry and can also create parts such as armaments, traditionally created through metal casting, resulting in reduced production time and increased output.

Measuring over 1.8 metres in diameter, the UAV was manufactured at Titomic’s R&D Bureau in Melbourne, Australia, where it houses the world’s largest and fastest metal 3D printer, the TKF 9000, measuring 9 x 3 x 1.5m and capable of rotational builds of 5m long and 2m in diameter. The system incorporates Titomic’s patented additive manufacturing (3D printing) technology, Titomic Kinetic Fusion (TKF).

Titomic Managing Director Jeff Lang stated: “We’re excited to be working with the global defence industry to combine Australian resources, manufacturing and innovation which will increase our sovereign capability to provide further modern technology for Australia and its defence force”.

Titomic Kinetic Fusion (TKF), co-developed with, and licenced from the CSIRO, is a patented metal AM process utilising supersonic deposition of metal powders to digitally manufacture metal parts and complex surface coatings of super alloys and dissimilar metals such as nickel, copper, scandium and alloys such as stainless steel, inconel, and tungsten carbide.

The additive manufacturing process feeds metal powders into a supersonic gas stream, which are then deposited onto a substrate. As the powders collide, kinetic energy causes the powders to mechanically fuse, building up layers of metal to form large, seamless metal parts without melting, allowing the fusion of dissimilar metals and materials.

With the unique ability to fuse dissimilar metals and materials, Titomic has unlocked opportunity to create unique materials and engineer parts and surface coatings that are unobtainable via other manufacturing methods. With ability to incorporate multiple metal alloys and materials into single, heterogenous parts, TKF enables the production of parts which exploit the mechanical benefits of multiple high-performance alloys concurrently.

The agility and versatility which the process enables will provide a step change in metals manufacturing and is not limited to particular industries. This is supported by Titomic’s variety of clients, ranging from global defence primes, through to global sporting goods manufacturers.

Titomic Kinetic Fusion™ offers unique capabilities, including:

- Ballistics armour plating & coatings

- Coatings for corrosion & erosion resistance and hypersonic applications

- Metallurgical fusion of dissimilar metals

- Improved buy-to-fly ratio for titanium parts

- Rapid part replacement

Titomic offers a range of engineering services, including:

- R&D & applications engineering

- In-house rapid prototyping services

- Component QA & testing verification

- Advanced manufacturing production

- Bespoke TKF production systems

- Metal powders & materials provider

Titomic offers this technology in multiple platforms, including:

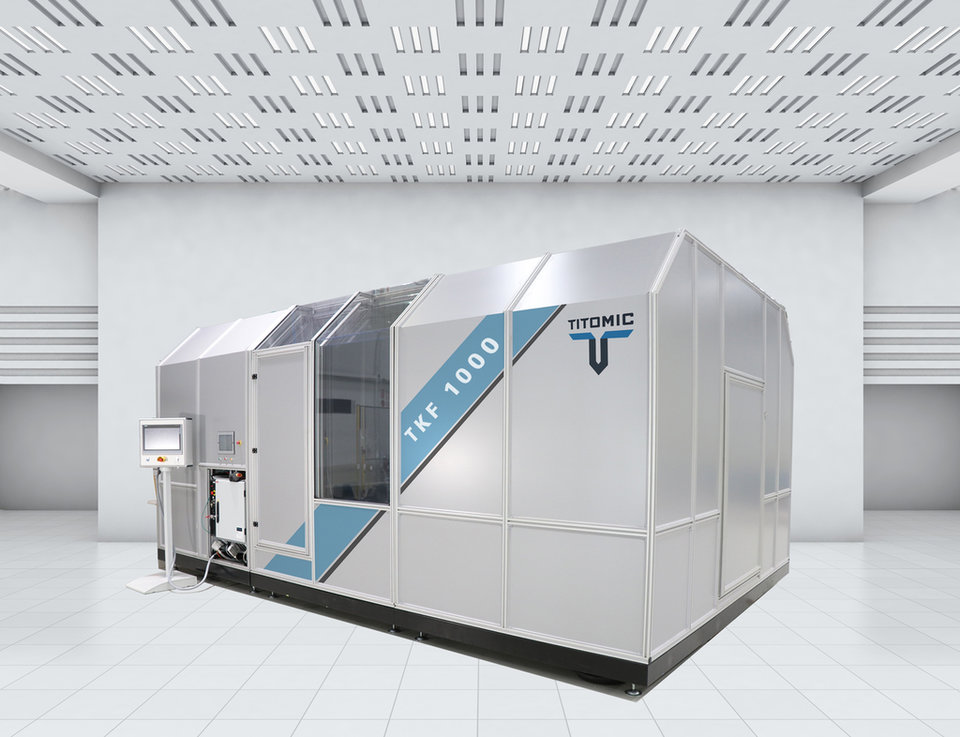

TKF 1000

Titomic’s new additive manufacturing system, engineered to provide compact Titomic Kinetic Fusion capability to all industries, academia and research organisations. The off-the-shelf, turnkey additive manufacturing system offers rapid, agile manufacturing, prototyping, research and development. With industry leading build rates and a build envelope of 0.75m3, the TKF1000 enables in-house manufacturing capability to increase self-reliance, reduce lead times and simplify supply chains.

Titomic offers this technology in multiple platforms, including:

TKF 9000

Introducing the world’s largest metal 3D printer; with a build envelope of 40.5m3 and industry leading build rates, the TKF 9000 is providing the new age of industrial scale additive manufacturing. The TKF 9000 demonstrates Titomic’s ability to provide bespoke production lines, providing manufacturers with custom built, autonomous robotic production lines capable of industrial scale additive manufacturing. Titomic’s additive manufacturing systems allow in-house, agile manufacturing, research and development utilising advanced materials.

About Titomic Limited:

Titomic (ASX: TTT) is headquartered in Melbourne, Australia. Titomic is positioned to change the value proposition of Titanium, to unlock new applications and open opportunities that are now technically and economically viable with its proprietary Titomic Kinetic Fusion™ (TKF) technology platform.

TKF overcomes the limitations of additive manufacturing (3D printing) for metals to manufacture complex parts without shape or size constraints. TKF offers production run capability to organisations, which enables speed-to-market, superior products with lower production inputs using fewer resources for a more sustainable future.

Titomic’s TKF enables first mover advantage in industrial scale manufacturing for sectors such as aerospace, defence, resources (oil & gas, mining, rail, chemical & industrial equipment), marine, construction, automotive, medical and consumer & sporting goods. For more information, visit: www.titomic.com.

Titomic's Past, Present & Future - 2019

get in touch!

Titomic Defence Applications

Head Office: Building 3, 270 Ferntree Gully Rd, Notting Hill VIC 3168

Mailing Address: PO BOX 225 Mount Waverley, VIC 3149

www.titomic.com

info@titomic.com