company insight sponsored by euroquartz

Oscillators for Commercial Off The Shelf Programs

COT’s components are not new to the defence and aerospace industries, but the momentum behind using Commercial Off the Shelf components, rather than highly specialized military equipment, has intensified in recent years.

This is partly due to the improved production quality of the industrial grade product that is now available.

For engineers the use of C.O.T.’s components is a matter of risk assessment and risk mitigation in their particular system design.

The correct choice of supplier is vital when procuring frequency components for this type of application.

A good supplier of crystals and oscillators should adopt a four-point mitigation strategy to ensure reliability and quality of the product.

1) Reliability Testing

Routine reliability data should be available for C.O.T.s parts, a typical cycle of reliability testing is shown below in figure 1.

2) Traceability:

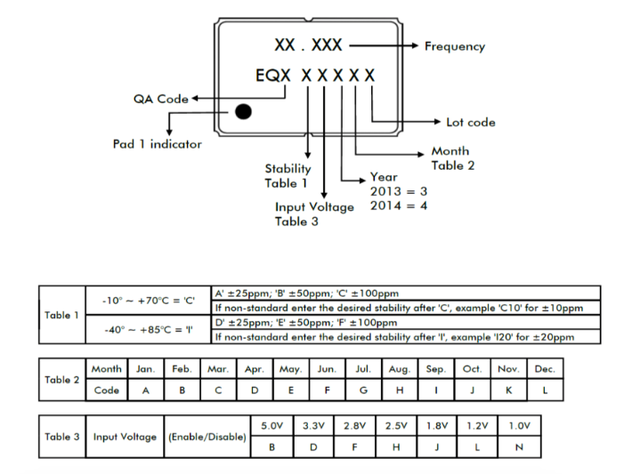

A date code alone is insufficient to provide production batch traceability it merely indicates the date the product was last tested prior to shipment. The inclusion of a lot-code will identify the exact production batch, operator and production line the parts were produced on. An example can be seen below in figure 2.

Obviously the prime motivation is to reduce the build cost of systems by down-rating some of the military specification components. However, care should be taken when purchasing industrial product for these applications as there are multitude of frequency product suppliers to choose from, all of which will have ISO9001 quality systems. Suppliers will often state that full traceability is offered, but in many cases the customer will not know where the factory is actually located other than a general statement of China or Taiwan, which then means that they are reliant on statements from the supplier. That is not to say that suppliers are not offering full traceability or just providing vague information, but in ISO9000 jargon, it should be demonstrable. In some cases customers may required specific tests to be performed which relates to some aspect of the application for instance; a restart test at a specific temperature, a good supplier will be able to offer this facility.

Another important aspect to consider is gold embrittlement, gold embrittlement and voiding can appear in SMT solder joints when using gold-finished components. This means that over time the components may become less reliable in terms of their mechanical bond strength to the PCB.

3) QA Access:

Free access to the production facility should be available even if the option is not taken up by the customer.

4) Stability of Supply:

Is the supplier able to demonstrate the stability of the supply chain, this is vital, especially as many C.O.T.s applications do not require huge volumes of product but could have an extended production life.

Obviously the prime motivation is to reduce the build cost of systems by down-rating some of the military specification components. However, care should be taken when purchasing industrial product for these applications as there are multitude of frequency product suppliers to choose from, all of which will have ISO9001 quality systems. Suppliers will often state that full traceability is offered, but in many cases the customer will not know where the factory is actually located other than a general statement of China or Taiwan, which then means that they are reliant on statements from the supplier. That is not to say that suppliers are not offering full traceability or just providing vague information, but in ISO9000 jargon, it should be demonstrable. In some cases customers may required specific tests to be performed which relates to some aspect of the application for instance; a restart test at a specific temperature, a good supplier will be able to offer this facility.

Another important aspect to consider is gold embrittlement, gold embrittlement and voiding can appear in SMT solder joints when using gold-finished components. This means that over time the components may become less reliable in terms of their mechanical bond strength to the PCB.

J STD-001 Revision “F “ states that gold shall be removed:

A. From at least 95% of the surfaces to be soldered of the through-hole component leads with >2.54 μm [100 μin] gold thickness and all through-hole leads that will be hand soldered regardless of gold thickness.

B. From 95% of all surfaces to be soldered of surface mount components regardless of gold thickness.

C. From the surfaces to be soldered of solder terminals plated with >2.54 μm [100 μin] gold thickness and from all solder cup terminals, regardless of gold thickness.

A double tinning process or dynamic solder wave may be used for gold removal prior to mounting the component on the assembly. Many customers will consider automotive approved parts manufactured to AEC-Q200, again care needs to be taken in this area as many of these components are produced for high volume usage and obtaining small quantities may present a challenge.

COT’s programmes will continue to grow in the years to come and it is up to both the customer and supplier to work closely together to ensure that risk mitigation is maintained.

get in touch!

EUROQUARTZ

Blacknell Lane, Crewkerne,

Somerset, UK, TA18 7HE

+44 (0)1460 230000

www.euroquartz.co.uk

info@euroquartz.co.uk

Go to top