Feature

In pursuit of failure: US military and predictive maintenance

The different branches of the US military are each looking to AI-powered predictive modelling software to improve readiness, forecasting equipment maintenance before such failures occur. Neil Thompson reports.

The US military has been slowly implementing predictive maintenance programmes into its services since the nearly 2000s. Credit: US Army

Predictive maintenance has been a defence priority for the US since 2002, when the country’s Department of Defense (DoD) first issued an interim predictive maintenance policy meant to improve over the more traditional policy of preventative maintenance method previously used to prevent equipment failure and keep US units battle-ready.

The DoD spends almost $90bn a year on weapons maintenance, making reducing accidents and creating cost savings without loss of efficiency an attractive option. However, the shift was slow to occur, even after the DoD in 2007 ordered the different branches of the US military to create a single focal point for predictive maintenance efforts, provide funding and begin implementation efforts where cost and feasibility justified it.

The US Army created its first predictive maintenance programme for its AH-64 helicopters in 2005 but extended this to the UH-60 helicopter line and some vehicle programmes only in 2012. It took another decade to install predictive maintenance systems on 65% of its CH-47F cargo helicopter fleet by 2022.

Nevertheless, in recent years predictive maintenance has begun to gain more traction, spurred by advancements and uptake in Machine Learning (ML) algorithms and Artificial Intelligence (AI); with the US Government Accountability Office (GAO) reporting in December 2022 that the US Armed Forces have begun piloting predictive maintenance schemes on some weapons systems.

The US military is exploring ways in which predictive maintenance tools can be utilised to improve readiness among its services. Credit: US Army

However, the GAO still found problems with the implementation of predictive maintenance, stating: “While the military services have begun piloting predictive maintenance programs on some weapon systems, they do not replace parts or components regularly based on predictive maintenance forecasts. [The] GAO found that the military services have not consistently adopted and tracked implementation of predictive maintenance.”

The private sector meanwhile already uses predictive maintenance systems such as condition-monitoring technology or data analytics in its operations, and defence contractors are keen to demonstrate the advantages of their tools to the DoD.

Mobilising forces’ data for maintenance insights

In October 2022, the US Army Materiel Command (AMC) agreed an ongoing five-year $85m contract with data analytics software firm Palantir Technologies to run the streams of maintenance, sensor, and supply data the AMC collects during its routine operations through Palantir’s predictive modelling software. The AMC would then use the software’s AI/ML capacity to find problem areas with its supply chain that prevented unit readiness, for example due to unexpected breakdowns, missing parts, or other issues.

"We are excited to support the AMC's predictive maintenance and supply chain optimization efforts," Palantir’s President Akash Jain said at the time. "Building upon our years of experience supporting the Army, we look forward to serving the logistics community and mission partners as they address such an essential aspect when operating in contested environments."

Palantir’s software and products like it have been used in the private sector for years, particularly in the airline industry.

We are excited to support the [Army Materiel Command’s] predictive maintenance and supply chain optimisation efforts.

Akash Jain, President of Palantir USG

However, AI/ML predictive maintenance software is now in use in the US Air Force, with the Air Force's Rapid Sustainment Office’s (RSO) Predictive Analytics and Decision Assistant (PANDA) system being designated RSO's System of Record for Condition Based Maintenance Plus (CBM+), the service announced in May 2023.

The RSO developed PANDA with the help of AI software provider C3.ai. The platform is now being used for maintenance operations for 3,000 aircraft across 16 organisational entities within the nine main Airforce command structures and generates an average of over 30,000 preventative maintenance alerts and recommendations according to the RSO.

“PANDA being designated as the Air Force’s system of record for CBM+ is a monumental achievement for the RSO and Air Force CBM+ enterprise,” said Chris Damani, RSO CBM+ programme office chief. “Alignment to one technology solution unites the sustainment enterprise to one tool and brings focus, dedication, and prioritisation of resources to PANDA allowing for further expansion, optimisation, and impact to mission readiness.”

The US Airforce also uses cloud provider Amazon Web Services to power PANDA as its internal legacy information technology systems are unable to provide the power and capacity needed to run a platform that tracks maintenance issues for such a large and complex organisation.

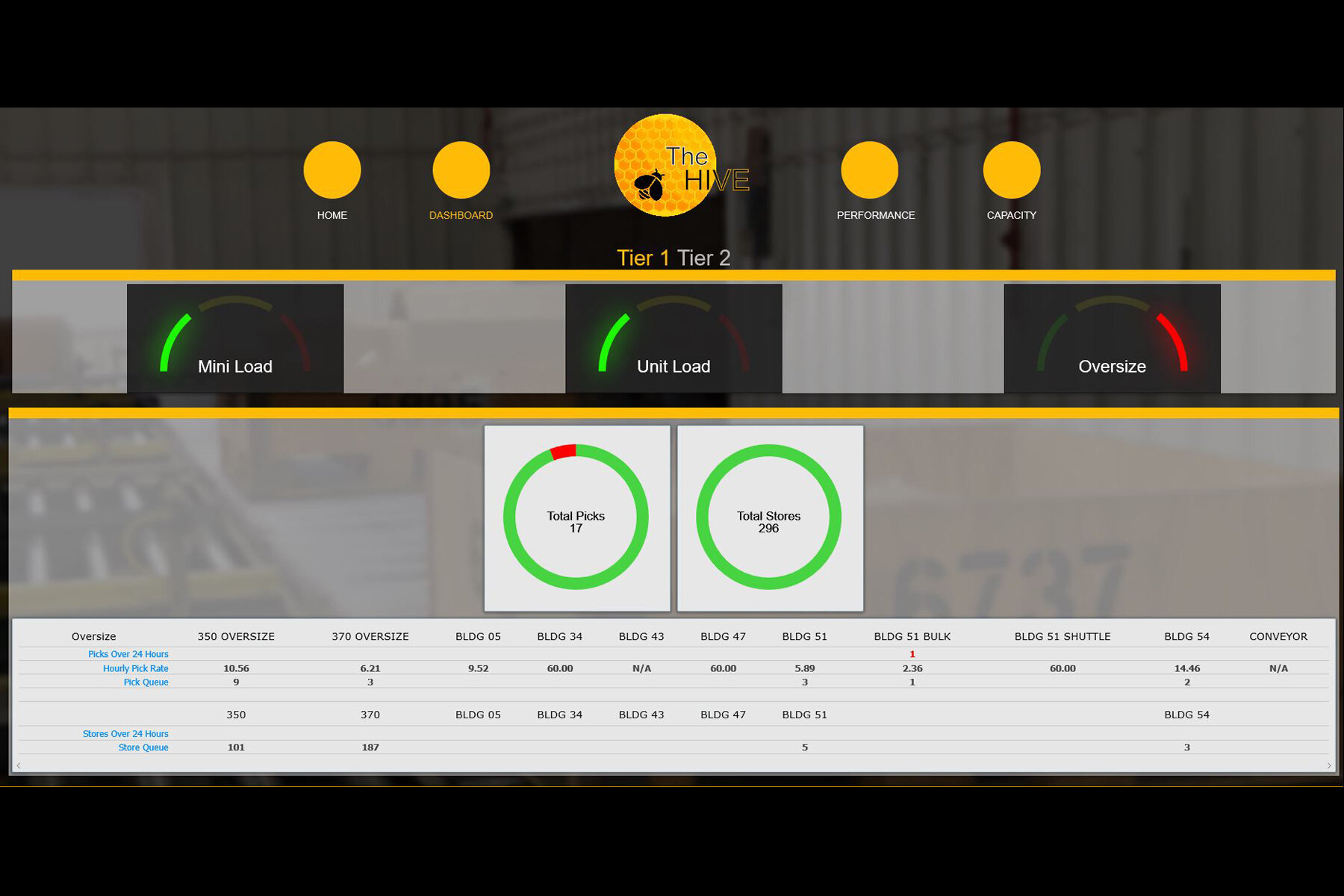

Development of programs such as The Hive at Letterkenny Army Depot have been intended to improve maintenance scheduling. Credit: US Army

The US Air Force operates across 59 air bases in the US and more than 100 airfields overseas; the service also controls over 5,400 aircraft, with an average age between them of 28 years. As a result, the AI platform needed to oversee the maintenance of such a complex and challenging entity requires the kind of computing power which only a global cloud provider could bring to the task.

Robotics and predictive maintenance platforms

The US Navy meanwhile authorised a $5m contract in July 2023 with a plan to combine an AI predictive maintenance platform data gathering by robots, which inspected several naval assets for damage and gathered data to be used in creating future digital models of warships. The long-term goal of the programme is to create structured data sets of naval assets which will enable the US Navy to scale up its approach to predictive maintenance in the future.

The US Navy’s use of hull-scaling robots linked to an AI platform is also expected to speed up and improve naval maintenance schedules for surface vessels significantly; with the software generating 4.2 million data points on one naval asset compared with just a hundred data points using traditional methods, creating a far more comprehensive picture of the vessel for engineers to monitor.

BAE Systems is looking to significantly expand the use of predictive maintenance insights and techniques in the maritime sector by global navies. The company has combined machine learning algorithms alongside data science to develop a Prognostics and Health Management (PHM) system for the naval sector.

According to the company, the tool uses the huge amounts of historical maintenance data BAE Systems has access to help inform engineers about both the current and future health of the assets in their care. Through analysing patterns, the PHM can identify a fault much earlier than may otherwise be the case without it, according to BAE, and potentially predict a fault before it becomes a problem on a vessel, thereby supporting engineering teams to improve their efficiency, freeing humans to focus on the engineering tasks that only they can still can do and increase the availability of kit by prolonging its life.

“This represents a potentially significant shift in how [naval] maintenance is carried out. Currently the approach is schedule based, meaning that some things are over maintained, resulting in time being lost to unnecessary work. By employing PHM to monitor, pre-empt and detect issues you can minimise maintenance time so that assets are kept in operation for longer,” said Robert Clifford, BAE’s Head of Digital Data, Maritime and Land.

Training AI predictive platforms for the future

Given that BAE Systems’ PHM can already detect ship’s upcoming maintenance issues, the defence company projects that the next step for preventative maintenance systems will be designing a product to help engineering and repair teams to determine the best course of cation for tackling the cause.

BAE Systems is working on a range of predictive maintenance programmes, including for the UK Royal Navy. Credit: BAE Systems

The company is now looking at how Large Language generative AI Models (LLMs) can be trained to generate technical solutions to problems the AI discovers. Currently, BAE Systems is trying to train its in-house LLMs by feeding them currently existing technical manuals and guides, with the aim of creating an LLM AI capable of generating a diagnosis and then recommending a course of action to humans, via an intelligent AI engineering agent.

The machine learning algorithms we have right now can provide valuable information for a human to make decisions

James Orrell, head of Engineering Projects Group at BAE Systems.

“AI agents like ChatGPT are progressing at an incredible rate. My personal opinion is that we’re still probably five to ten years from AI agents taking the lead in this instance in this area and within the defence industry,” said James Orrell, head of Engineering Projects Group at BAE Systems.

“The key to this is demonstrating the value of these AI solutions along the way to this future goal. We have to build confidence in these solutions before people will be willing to take recommendations.

“The machine learning algorithms we have right now can provide valuable information for a human to make decisions. The more we do this, the more of this decision-making process we can capture and use to inform AI agents.”

Australia could be one of the main beneficiaries of this dramatic increase in demand, where private companies and local governments alike are eager to expand the country’s nascent rare earths production. In 2021, Australia produced the fourth-most rare earths in the world. It’s total annual production of 19,958 tonnes remains significantly less than the mammoth 152,407 tonnes produced by China, but a dramatic improvement over the 1,995 tonnes produced domestically in 2011.

The dominance of China in the rare earths space has also encouraged other countries, notably the US, to look further afield for rare earth deposits to diversify their supply of the increasingly vital minerals. With the US eager to ringfence rare earth production within its allies as part of the Inflation Reduction Act, including potentially allowing the Department of Defense to invest in Australian rare earths, there could be an unexpected windfall for Australian rare earths producers.

Credit: US Department of Defense; Department of Energy (originally compiled by Neta Crawford)

Total annual production

$345m: Lynas Rare Earth's planned investment into Mount Weld.

Caption. Credit:

Phillip Day. Credit: Scotgold Resources