company insight sponsored by omnetics connector corporation

Omnetics’ Fast Turn Miniature Connectors

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut sed consequat felis. Nunc viverra mattis vulputate. Etiam bibendum metus nunc, ac hendrerit nisi lacinia id. Duis a purus sed ex laoreet dapibus non accumsan sem. Cras laoreet ut eros a interdum. Vestibulum dolor lorem, feugiat elementum gravida nec, mattis vitae ante.

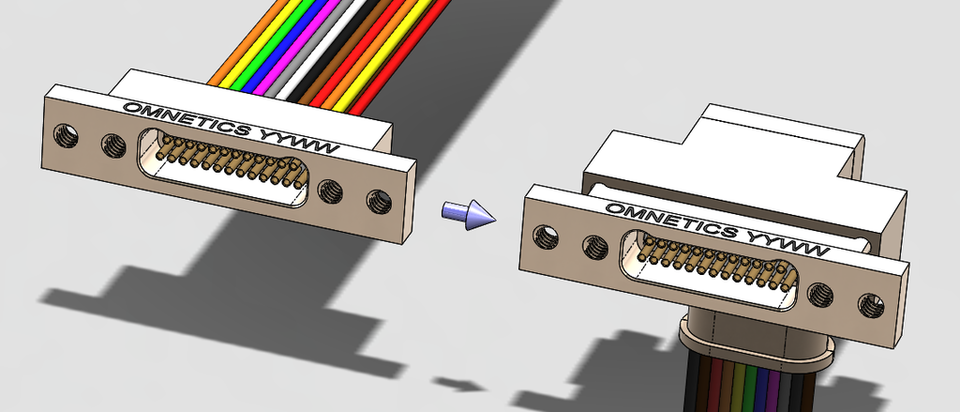

New connector forms are rapidly designed using proven connector and materials as a reference to modify shape, size and function. Tailored connectors will often solve new instrument needs and secure high reliability performance based on proven materials and processes from our established standards.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

A frequent question today: “How do I design a special connector to solve my new system requirements?”

Omnetics has a direct Three-Step-Process. Our application-specific connectors will meet your needs and be available on-time!

- Designers can view miniature connectors with proven performance on our websites or discuss with our sales team. If one looks close, ask for a sample or discuss variations on email or the phone.

- Connect with an Omnetics connector designer for on-line collaboration making a new solid model of exactly what is needed in as little as 2 days.

- When you like the solid models, ask for a 3D sample made using automated material added process. This should take less than 24 hours.

The new 3D model is shipped to the customer to fit it into his new application for final approval or/and re-define some specific change needed.

Omnetics Connector Corporation is a privately-owned company with over 30 years’ experience in designing and building ruggedized miniature connectors for the Micro and Nano-electronics industry. With over 400 direct employees, all products are built in the Minnesota factory in compliance with ISO 9001 offering QPL products to MIL-DTL-83513 and MIL-DTL-32139 and are ITAR registered.

High technology markets using Omnetics products include: military and aerospace, high end, medical technologies, petroleum and orbital satellites in space. In addition, you are also served by Omnetics worldwide Sales Representative force and Digikey, that you can schedule a direct discussion with.

Table 1: Areal weight comparison of glass and ceramic – glass composite armour windows (available on the market)

Modified connectors are highly used to combine signals in what we call mixed-signal or hybrid connectors. Coax and power signal are routed through the same connector and cable as multiple digital signals. This significantly reduces the size, weight and routing complexity for the system designer. Specific applications using Omnetics connectors include high speed soldier borne and helmet communication cables, connectors for cube satellites, orbital radio circuitry on satellites, UAV controls, surveillance system digital data connectors, missile control electronics, robotic interconnections, spinal modulation, prosthetics, catheter cable to monitors and more.

Defense and orbital space instruments are leading way in solving many new requirements. The race to manage individual satellites and protect the instruments has evolved rapidly as multiple nations are placing necklaces of satellite constellations to increase surveillance, earth-based tracking and guide potential weapons. These critical elements have also changed the rules in cable and connector design. Omnetics’ Nano-D connectors have a proven record for rugged and light-weight performance in handling a multiple of on-board signals systems within space modules. However, Nano-Ds are being required to solve additional issues.

As EMI (electro motive interference) can interrupt and add noise to signals within the cable, the need to protect against laser beams, solar radiation and focused cyber interference have moved cable connection to a new level. Shielded cables are being routed from power and surveillance units to full metal shielded panel mounted connectors. The modified Nano-D is a great example of a system designer specifying a 360-degree full-metal back shell that can be mounted face-out to receive a shielded Nano-cable. Different grades of shielding can be specified from highly flexible fabric shields to slide-over braided shields at 65 db of isolation to building a braid-wrapped shielding system that can achieve up to 90 db of EMI insulation. Specific back-shell size and shapes are worked out with the connector designer during an on-line solid-modeling session. Metal shells can be made in many options, such as aluminum plated with electroless nickel or of stainless steel. Multiple standard or custom plating are available. Most often, connector plating meets the military standard of nickel and gold. Plating can also be modified for even higher EMI protection by increasing the surface conductivity of the shield using low resistance gold for nearly total signal isolation. This later method is often specified with miniature coax cable routing microwave signals within a satellite unit.

Table 1: Areal weight comparison of glass and ceramic – glass composite armour windows (available on the market)

Omnetics is a world leader in miniature connector solid-model design partnering with customers to provide perfect-fit cable and connectors for advanced applications. Using 24-hour 3D material added processes designers can conceive, model and build test devices quickly to meet their needs.

See Omnetics website or call our local sales representatives to begin a discussion on the many low cost, rapid development options available.