company insight sponsored by curtiss-wright

DuraCOR Mission Computers

Innovating smaller, stronger, smarter, and faster defense solutions

Mission computers are at the heart of every military platform. That’s why delivering field-proven, highly engineered technology that warfighters can trust is at the core of what we do.

Curtiss-Wright’s rugged commercial-off-the-shelf (COTS) mission computer subsystems in the small form factor (SFF) Parvus® DuraCOR® product line feature modular, expandable designs, and powerful graphics and data processing capabilities, integrated together in an ultra-reliable and robust chassis.

With decades of experience developing small, smart, fast, and strong defense solutions, Curtiss-Wright has engineered its DuraCOR product family from the inside out to address stringent size, weight, power, and cost (SWaP-C) requirements. This enables our customers to deploy a fully-functional, environmentally-hardened subsystem — tailored to specific needs — in a matter of weeks.

These field-tested, MIL-STD qualified mission processors have been proven in C4ISR technology refresh and platform upgrade programs under thermal, shock, and vibration extremes in unmanned and manned aircraft, ground vehicles, and maritime platforms.

Expandable

Each unit features electrical/mechanical I/O expansion capabilities that enable rapid integration of payload-specific I/O interfaces for avionics, vetronics, situational awareness, and other applications.

Curtiss-Wright provides application engineering services to extend base system computing functionality for these small form factor SFF systems, adding in application-specific I/O and communications cards—typically without traditional NRE fees or development project delays.

With pre-integrated, pre-qualified subsystems tailored by the factory, DuraCOR customers dramatically reduce scheduling risk and program management overhead, while maximizing use of open architecture COTS technologies.

DuraCOR 312 Hardware from Curtiss-Wright

The Parvus DuraCOR 312 from Curtiss-Wright is an ultra-small form factor (USFF) modular mission computer built around the high-performance, yet power efficient NVIDIA® Jetson™ TX2i “supercomputer-on-a module” computing device that is integrated in a miniature rugged chassis with MIL-grade high-density connectors.

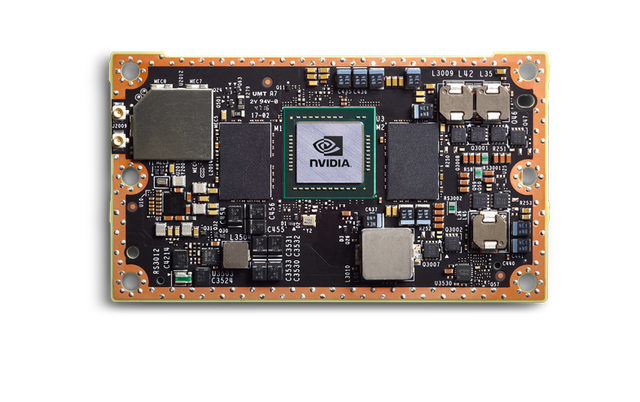

NVIDIA Jetson TX2 module

The DuraCOR 312 combines powerful NVIDIA Pascal™/CUDA-core GPU signal processing with 64-bit Armv8 heterogeneous multi-processing (HMP) for size, weight, power, and cost (SWaP-C) sensitive mobile, airborne, ground, manned, and unmanned vehicle and sensor platforms. The unit also integrates a massively parallel, many-core architecture boasting one of the highest computing FLOPS-per-watt architectures on the market.

Thanks to the unit’s Pascal GPU architecture (supporting Max-Q and Max-P dynamic energy profiles), larger memory bandwidth, and support for CANbus, the DuraCOR 312 can deliver up to twice the performance or power efficiency of TX1-based systems together with native vehicle bus interfaces.

Modular Design

The unit also delivers an unparalleled modular system design, boasting multiple Mini-PCIe I/O card slots, high-speed M.2 internal storage, removable SATA Flash SSD capabilities, and an aerospace-grade power supply supporting 50 ms power hold-up. This is all contained in a fanless IP67-rated mechanical package designed for wide temperatures and harsh shock and vibration, along with ECC memory for mitigation against single event upsets at high altitudes.

While the low-power DuraCOR 312 is miniature in size, this rugged COTS mission computer LRU packs performance with six (6) Armv8 processor cores and 256 Pascal/CUDA-core GPU along with multiple add-on I/O and storage expansion options to support additional vetronics/avionics interfaces beyond its already comprehensive set of base I/O (which include Ethernet, CAN, serial, USB, DIO, and video ports).

The unit comes with on-board eMMC Flash and supports an optional internal M.2 SSD (NVMe/SATA), as well as optional removable 2.5” SATA SSD storage for high capacity storage and information assurance requirements. Like other DuraCOR models, the 312 leverages both an ecosystem of rugged COTS Mini-PCIe modules (including MIL-STD-1553 and ARINC 429 avionics databus interfaces) and Curtiss-Wright’s responsive, cost-competitive application engineering services to deliver Modified COTS (MCOTS) variants quickly and without a traditional NRE fee.

Ruggedized for Harsh Conditions

With military-grade ruggedization to extend Jetson TX2i operation, the DuraCOR 312 is designed to operate reliably in extremely harsh environments, making it well suited on-board civil and military aircraft and vehicle platforms.

Comprehensive qualification testing validates its robustness under MIL-STD-810G, MIL-STD-461F, MIL-STD-1275D, MIL-STD-704F and RTCA/DO-160G conditions for environmental, power, and EMI (thermal, shock, vibration, dust, water, humidity, altitude, power spikes/surges, conducted/radiated emissions and susceptibility). In addition, optional 50 ms power hold-up capabilities are supported for MIL-STD-704F aircraft power switch-over requirements.