Company Insight

Sponsored by Omnetics Connector Corporation

Rugged Interconnect Systems for On-board Mobile Electronics

Omnetics is a dedicated military level interconnection systems developer with over 35 years of experience. Our design manufacturing and Quality department have proven products operating in areas such as on MARS, in Satellites and the Battlefield.

Defense system design trends have advanced to using an organized collection of remotely coordinated management and support technologies that remain in constant communication with many remote portions of the battlefield arena. Satellite data and communication centers relay surveillance data, current and planned positioning of planes, ships and ground based warriors. Dismounted soldiers use the system to assist in directing autonomous drones, remote weapons and to provide constant communication with the tactical leadership team. Condensed portable modules are carried on the soldiers’ uniforms as well as mounted into helmets, weapons and in support of antennas and LIDAR based surveillance devices.

Above and beyond the call of duty

Improved mobile systems required new platforms focused upon reduced size, low weight, minimal battery or power demand and often, higher speed digital electronics. The newer ballistics and air-to-ground missiles are smaller, fly faster and carry their own GPS guidance systems exposing them to high inertial stresses. Using basic physics, we are reminded that size and weight play a key role in acceleration as well.

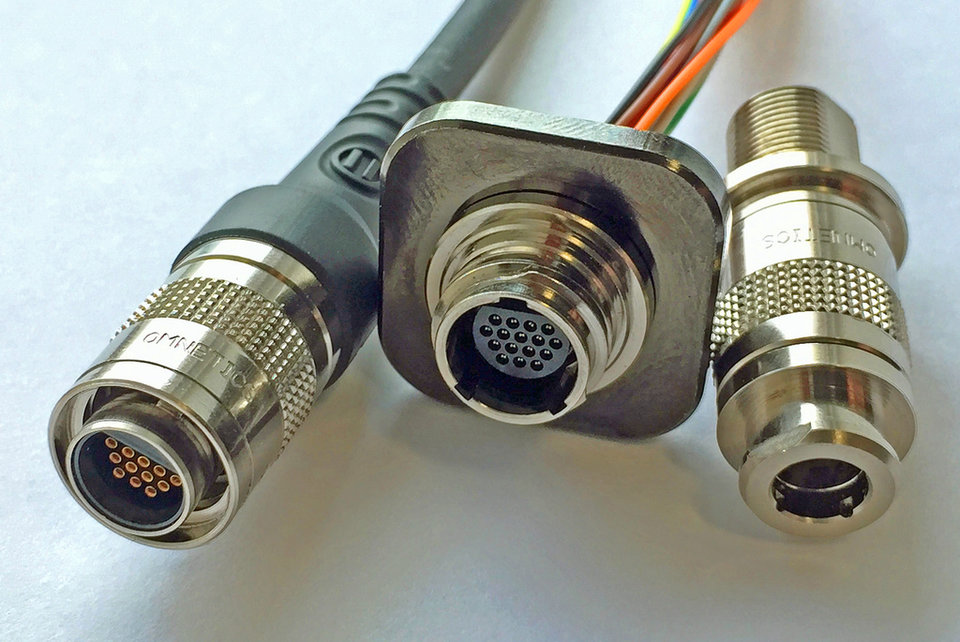

Nearly all equipment will see a mix of constant vibration during surface-travel, shock during drone landings and high acceleration of missile flight that challenges the mechanical strength. On board electronic devices and interconnections routing data to and from module to module within the equipment must also be designed to meet those challenges. Omnetics is key defense connector and cable design company supplying full military qualified Micro and Nano Connectors and cables for these exact purposes.

Meet today's tough data security compliance and exceed even the toughest government regulatory standards with kanguru.

// Nano-D Connectors

Direct support in meeting electronic design trends for the defense industry starts by working with connector and cable design companies focused on meeting and exceeding the extensive list of military reliability and performance challenges. Connector companies with proof of that experience is in the battlefield today. Good examples begin with Nano-D connectors built to MIL-DTL-32139 specification and using non-outgassing materials for continuous performance in small satellites in defense orbiting communication systems. Orbiting satellites can focus on one specific battlefield by flying over it 7 to 10 times a day. The orbits cause multiple thermal cycles that interconnections must survive. Ground based autonomous weapons include digital surveillance cameras and GPS reporting electronics to help maneuver a wide range of mud, soil and vibration conditions.

Micro-D and Nano-D connectors are made to withstand these events by using single piece BeCu (beryllium copper) pins plated with military level plating of nickel and gold to prevent contact wear. Connector size and electrical current demands are planned to specifically match the machine design. In many cases connectors are designed carry a mix of larger pins and wires to support a power unit or a steering cam, simultaneously with smaller pins and wires to rapidly deliver high-speed digital data from cameras or GPS within the weapon. These hybrid connector and cable systems are specifically customized for each weapon from key elements of current military connectors. They are tested to the ruggedization requirements of the new weapon and or to specifications by the system developer.

// Ratcheting Micro

Defense equipment evolution is also pushing for scaling down the size of circular connectors while increasing the signal speed for use in the field. The popular MIL-DTL-38999 circular connector uses 18-20 size pins to carry up to 12 Amps on 20 AWG wiring while miniature military 38999 connector is being standardized by a number of companies that will be a smaller and more universally available.

One example is Omnetics Micro Circular connector with a triple-start thread coupling system. It is designed to mate quickly in gloved-hands and insure EMI shielding.

This new standard will offer size 23 pins and smaller to handle ranges from about 10 Amps down to smaller pins for approximately 3 amps, on 24 to 30 AWG wire. Some of the smallest circular connectors use size 30 pins, support 1 Amp and 30-32 AWG wiring. Pin–to-pin spacing drops from over 75 mils to 25 mils. This reduces the diameter of both the connector and the cable. Cable flexibility improves simultaneously.

As defense designs continue to evolve, designers can work directly together with solid model designers, at companies like Omnetics. A key to rapid design includes making a table of electrical performance, power, size and weight requirements. Expanding the list could include listing the expected environmental application that the system will be used. With this data, a designer can speed up connector selection or customization process and help the prototype stage of development. When size, shapes or mixed-signaling requirements are needed, a solid model is formatted and sent to the defense design company. Adjustments can be made on-line and when finally approved, a 3D model can be fabricated in two to three days and sent to insure design fit within tight or unique shaped spaces.