company insight

PERLUCOR® - for High Performing Transparent Multi-Hit Solutions for Every Mission

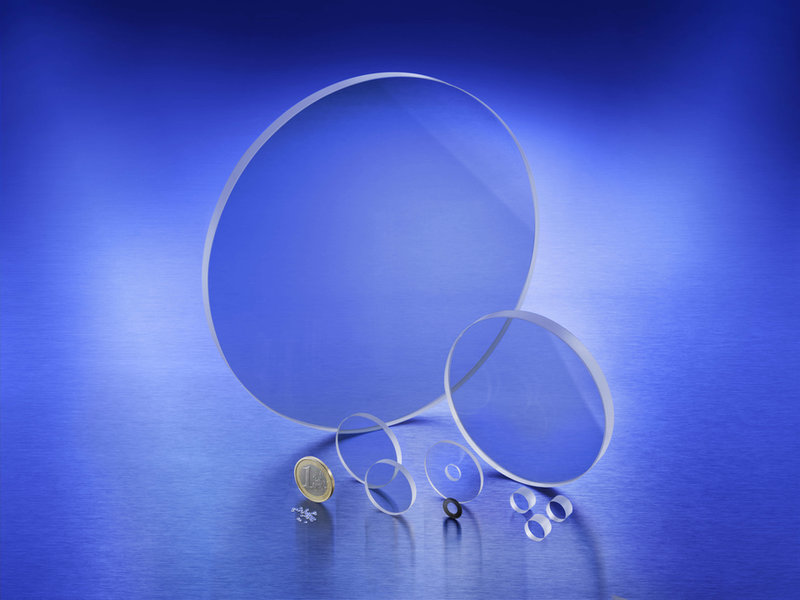

Ceramics’ manufacturer CeramTec is the first European company having developed series-ready transparent ceramics. High weights and thicknesses as well as low resistance against scratches and rock falls have always been major problems for existing transparent armour or optical systems. Using PERLUCOR® eliminates these shortcomings.

CeramTec-ETEC is a well-known producer of Alumina and Silicon Carbide based opaque armour ceramics for nearly 30 years. CeramTec’s ceramics can be found in most of the German military vehicles equipped with composite armour, as well as many of those built by other European or worldwide countries.

Intensive research and development work enabled CeramTec specialists to successfully transfer the advantages of ceramics to the world of transparent materials. The history of transparent ceramics suggests it hadn’t been that much of a success story, which CeramTec believed to be down to the high costs associated with it. With that in mind, the company started to develop a completely new process.The result is a material offering an affordable alternative to Sapphire glass at up to 60% lower costs. Its name is PERLUCOR®

Transparent armour applications

Non-transparent armour for military vehicles has been improved over the past 20 years from heavy steel solutions to exceptional light composite systems including various ceramic materials. Today’s solutions for STANAG 4569 protection Levels 1 to 4 are all well below 100 kg/m².

Current conventional transparent armour solutions for vehicles made out of glass/polymer laminates are heavy and bulky. An average system e.g. for STANAG 4569 Level 3 has an areal weight of approx. 180-200kg/m² with a thickness of 90-100mm. Level IV windows are available at a weight of approx. 420kg/m² with 200mm thickness.

Using PERLUCOR® transparent ceramics as a front layer to replace part of the glass one can achieve weight and thickness reductions of 30 to 60%. In such a way, the absolute areal weight savings for level 2 to 4 requirements can range from 50 to more than 150kg/m².

Table 1: Areal weight comparison of glass and ceramic – glass composite armour windows (available on the market)

Furthermore, the requirements concerning the multi-hit capability for transparent systems are also lower in comparison with the opaque field. With the ceramic multi tile front layer, it is possible to reduce the distance between 2 bullet hits from 120mm (current test method) to 50mm depending on the size of the ceramic tiles.

Optic and Optronic Applications

The crew and especially the driver of military vehicles depend more and more on optic and optronic equipment such as cameras, infrared imaging and targeting equipment, periscopes and other sensors to fulfill their mission successfully on today’s modern battlefields. Under harsh environmental conditions, as they occur in deserts or semi deserts, the operational readiness of such equipment might be heavily reduced, if sand or small rocks damage the surface of the optics. Thin layers of PERLUCOR® can help to increase the lifetime of such highly valuable as well as sensitive optical equipment, keeping it fully functional during combat. Results of the sand blower test according to MIL-STD-810G: Method 510.5, Procedure II has shown that the transparent ceramic does not show any measurable loss in transmission (increase in haze) compared to Borosilicate Glass with nearly 10% loss in transmission.

Because of its very high chemical and heat resistance and an excellent transparency up to 6 microns (medium infrared wavelength), PERLUCOR® can be used in many other applications, where glass based materials do not offer satisfactory solutions or other sophisticated materials such as sapphire do not represent a cost effective option. An example would be the domes for rocket sensors or windows for sensor suites on aircrafts and drones. In this case, PERLUCOR®’s advantage would be its better transparency at higher temperatures (above 600°C) compared to sapphire. For EMP purposes PERLUCOR® can becovered as well with special metal grids and /or coatings

For special optical applications, requiring higher transmission, CeramTec-ETEC has developed together with a partner company a new extremely hard anti-reflective coating PERLUCOAT Ultra, working exceptionally well with PERLUCOR® as a base material. It is increasing the transparency to above 92% if used as a one-sided coating or even up to 95-97% if applied on both sides of the PERLUCOR® lens. Wear test results have shown that the AR coating on top of PERLUCOR® performs much better than hardened and special “scratch resistant” glass available on the international market.

Summarized, PERLUCOR® has proven to be an excellent material used within transparent ballistic and optical/optronic applications, giving the customer a high performing multi-hit solution with a much lower weight and thickness, an increased lifetime with a very reasonable cost/performance ratio compared to compatible materials.

Certified STANAG 4569 Level 4 Test Panel 500x500mm tested with 3 shots 14,5mm API bullets at high temperatures, manufactured by Oran Safety Glass, areal weight approx. 220kg/m², thickness approx. 100mm, using transparent ceramic PERLUCOR® from CeramTec-ETEC