Company Insight

Sponsored by Sky Power

Propulsion as a Strategic Enabler

Sky Power’s Playbook for Longer-Range ISR and Mission Readiness

Main image: Karsten Schudt, CEO of Sky Power International

In this exclusive Interview, Sky Power International CEO Karsten Schudt explains how intelligence, surveillance and reconnaissance (ISR) demand, hybridization, and geopolitics are reshaping UAV propulsion—and why engines are a strategic enabler, not a commodity.

ATERMES has been at the forefront of this shift. With decades of field insight and direct collaboration with defense partners, we’ve engineered solutions that meet the realities of modern conflict. Our SURICATE system is a clear example, fusing thermal and visible-spectrum sensors with onboard AI to autonomously monitor, detect, and classify threats. Designed for harsh conditions and mission-critical deployments, SURICATE doesn’t just observe, it learns. With every deployment, it refines its detection algorithms and feeds smarter insights into the next operation.

Still, the true power of this evolution lies in the partnership between human operators and machine intelligence. This is not man versus machine. It’s man with machine. AI lightens the cognitive load, sifts through the noise, and presents operators with only the most relevant, high-confidence information. That means fewer errors, faster command decisions, and tighter operational coordination.

In a region defined by both opportunity and instability, this capability is no longer optional. Middle Eastern defense forces must outpace threats that are becoming more autonomous, decentralized, and agile. Nations that embrace intelligent, field-adapted systems will hold the strategic upper hand, not just in detection but in deterrence.

As Lionel Thomas, Chairman of ATERMES, notes: “In the Middle East, where defense forces operate across vast borders, challenging terrain and evolving threat landscapes, Artificial Intelligence is becoming an indispensable ally. We believe that pairing AI with advanced vision systems unlocks a new level of battlefield intelligence where threats are seen earlier, understood faster, and addressed with greater precision.”

At ATERMES, we’re not waiting for the future. We’re building it in partnership with those who serve. Our roadmap is shaped by mission feedback, driven by real-world needs, and anchored in technology that works where it’s needed most. We're doubling down on systems that think at the edge, because the battlefield won’t wait, and neither will we.

In modern defense, clarity isn’t a luxury, it’s a weapon. AI and multispectral vision deliver it. Not in theory, in the field. Not someday, now.

In early June 2019, mining companies avoided increases to royalties by agreeing to provide A$70m to a A$100m infrastructure fund.

Frank Smith, Founder and CEO of TowHaul

Phillip Day. Credit: Scotgold Resources

Army Technology: What is Sky Power’s core purpose and promise?

Karsten Schudt: Our goal is to deliver reliable, efficient, ready-to-use propulsion systems for unmanned and mobile applications. With deep expertise in UAV engines, we stand for high quality, reliability, and technological excellence. We provide tailored solutions with full lifecycle support so platforms stay operational longer, carry more payload, and meet demanding certification and mission standards.

Army Technology: Which shifts shape your strategy—and why do they matter?

Karsten Schudt: Three major changes are shaping our roadmap:

- The increasing demand for reliable propulsion solutions due to the global geopolitical situation

- The demand for ever greater ranges, especially for ISR missions

- Hybridization of UAVs to extend range and logistical flexibility

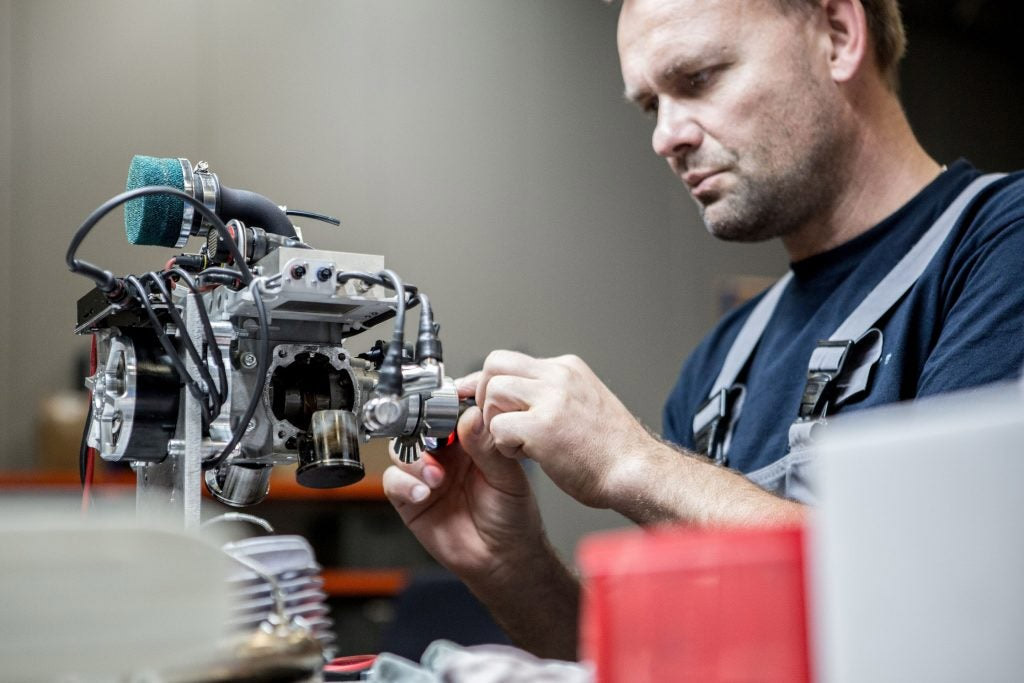

Army Technology: What was the biggest lesson Sky Power learnt from scaling prototypes to fielded systems?

Karsten Schudt: The most important lesson is to collaborate with integrators and end users from day one. Lab or stand tests alone are not enough; propulsion must be validated in realistic conditions. Early collaboration shortens time to market and boosts reliability.

Caption. Credit:

Army Technology: How do you prioritize markets and product areas?

Karsten Schudt: We know what UAS customers need. We develop options for current and future products based on that. For example, years ago, we saw the push for low fuel burn and longer ranges. We designed for that—fuel injection, CAN-bus communication—so our engines fit ISR missions today.

Army Technology: What differentiates Sky Power for buyers and partners?

Karsten Schudt: A broad portfolio: powerful two-stroke engines, efficient Wankel engines, HF and hybrid systems, and generator solutions. All reflect German engineering and manufacturing quality, backed by global support network. With flexible customization and targeted services—maintenance, engineering, test runs, project management—customers get tailored, future-proof propulsion. This combination is rare.

Caption. Credit:

Army Technology: How do you balance near-term opportunities with long‑term R&D?

Karsten Schudt: We reserve a fixed portion of our revenue for core R&D so that innovation continues even during busy production cycles. The results and experience gained from projects then serve as a source of innovation for gradual improvements that are incorporated into our long-term roadmap.

Army Technology: How do partnerships with OEMs, integrators, and primes drive growth?

Karsten Schudt: We treat them as strategic partners, not just customers. Joint engineering teams, collaborative development efforts, and clear program milestones ensure that everyone benefits from reduced risk and faster delivery, ultimately resulting in propulsion systems aligned to mission requirements.

Army Technology: How do you simplify procurement evaluations?

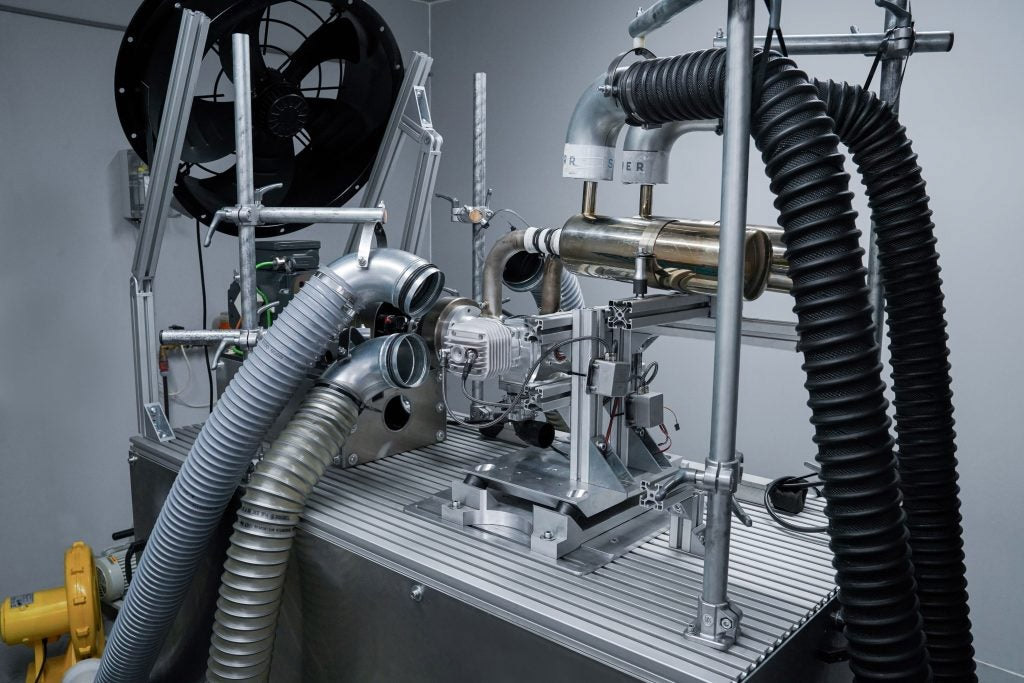

Karsten Schudt: We run extensive tests on in-house benches and share the data with our customers upfront. This lets customer teams compare total operating costs and integration schedules without any hidden surprises.

Caption. Credit:

Army Technology: How do you measure outcomes like readiness, uptime, and TCO?

Karsten Schudt: Many applications are confidential, but our test benches—especially FAR33 long-term tests—yield key data. We measure operational readiness, MTBF, fuel consumption, maintenance intervals, and cost per operating hour, and share dashboards or case studies with customers. This data informs product development and helps customers decide.

Army Technology: Which commercial models are you prioritizing to accelerate adoption?

Karsten Schudt: In addition to sales, we offer services ranging from early project definition to series production. We provide consulting services to help clarify goals and requirements and contribute technical expertise. In workshops, we analyze ongoing projects together to clearly define requirements and expectations and prepare for close cooperation. Through project management, we control the process from concept to series production, with clear parameters, schedules, and budgets for agile and efficient development.

Army Technology: How do you ensure scalability, supply resilience, and quality?

Karsten Schudt: We work with local manufacturers for critical parts to ensure rapid exchange. We generally work with our suppliers for a very long time, so that a long-standing partnership has developed based on this trust. Since we source some parts from all over the world, we place great importance on quality assurance and testing when the parts arrive at our premises. That is why we have invested in sophisticated testing equipment to measure cast parts in order to ensure smooth and reliable engine operation.

Army Technology: How do you balance commercial priorities with environmental and social responsibility?

Karsten Schudt: In new designs, we emphasize fuel efficiency, lower emissions, and reusable components, and we work with suppliers who meet strict environmental and occupational safety criteria. That reduces our environmental footprint and customers’ compliance risks.

Army Technology: What misconception about propulsion suppliers would you correct?

Karsten Schudt: That “an engine is a commodity.” In fact, the propulsion system determines the payload, endurance, safety, and lifecycle costs. If it is viewed as a strategic subsystem rather than a commodity, significantly better mission economics can be achieved. Furthermore, the engine is the critical component for reliable UAVs and a successful mission. Purchasing decisions that are solely price-driven usually lead to increased costs down the line, as “promised” ranges or similar specifications are not met. Unfortunately, we have found that projects and market launches have been delayed by purely price-driven decisions in favour of an engine, and the entire project had to be restarted from scratch.

And never scale too small. Of course, a propulsion unit weighs something, and this must be taken into account in the project planning from the beginning. This means that in order to meet the target specifications, you must plan for an engine with sufficient power. Attempts should not be made to achieve targets by reducing the engine weight through the selection of a smaller propulsion unit. However, this also means that we as engine specialists should be involved in new projects as early as possible.

Army Technology: Key milestones you want customers to remember—and your message to procurement?

Karsten Schudt: I have a clear message for development managers and procurement officers: Choose the propulsion system as a strategic enabler. At Sky Power, we are your partner, supplying engines, support packages, components, spare parts and knowledge that support and protect your mission and your budget.

Army Technology: Karsten, thanks for cutting through the noise on what really drives mission economics. We look forward to tracking Sky Power’s next milestones in hybrid range extension and lifecycle support as ISR and multi-mission UAS requirements continue to scale.

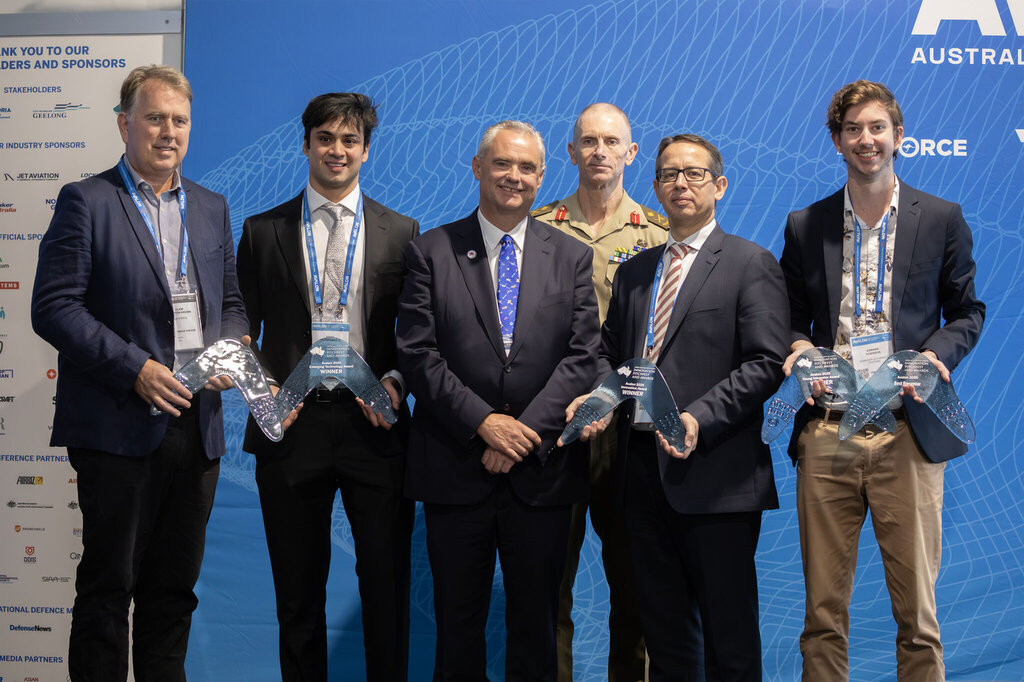

Innovation at the Forefront

Avalon 2025 continued to serve as a launchpad for cutting-edge technology, with the Innovation Pitchfest and Awards providing a stage for breakthrough ideas. Judges praised the exceptionally high calibre of entries, with 23 finalists competing for prizes.

Four winners emerged, securing a combined $130,000 in funding to propel their innovations forward:

Avalon 2025 Innovation Award: Herve Aster, Neumann Space

Avalon 2025 Young Innovator Award: Edward Robinson, Robinson Aerospace

Avalon 2025 Emerging Technology Award: Nishq Ravindranath, Akula Tech Pty Ltd

Avalon 2025 Blue Sky Thinking Award: Clem Newton-Brown, Skyportz

Keynote speaker, Mike Henry. Credit: PDAC

Contact information

Sky Power GmbH

Tel.: +49 (0)6172 – 594 9005

Email: info@skypower.online

Web: skypower.online

- Biffa internal savings data, average saving (January - August 2023)

- Nisbets internal savings data, average saving (January – September 2023)

- Compliance365 internal data, average savings

- HEINEKEN UK data, Calculations based on SmartDispense® active accounts each year since 2015 with 10 lines

- Independent test results based on subterranean and ground floor pub cellars of varying sizes

- Independent test results based on subterranean and ground floor pub cellars of varying sizes