Company Insight

Sponsored by Viscom

Discover Viscom

Precision Inspection Technology for Mission Success

Main image: Karsten Schudt, CEO of Sky Power International

For more than four decades, Viscom has focused on one essential mission: helping manufacturers achieve 100% defect-free products. The company designs, engineers, and manufactures inspection systems in Hanover, Germany that e.g. safeguard the integrity of the world’s most critical electronics. Even the smallest hidden defect can jeopardize performance, compromise safety, or disrupt operations. Viscom ensures that these risks are eliminated before they can impact the field. By delivering world-leading inspection solutions tailored for demanding and highly regulated environments, we help customers detect, understand, and eliminate defects before they can threaten mission readiness.

In early June 2019, mining companies avoided increases to royalties by agreeing to provide A$70m to a A$100m infrastructure fund.

Frank Smith, Founder and CEO of TowHaul

Phillip Day. Credit: Scotgold Resources

What Viscom does and why it matters

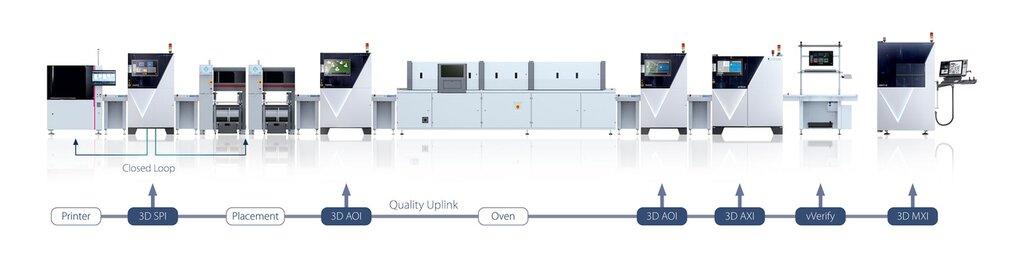

Viscom offers a broad portfolio of inspection solutions tailored to the needs of high-reliability electronics. The inspection systems are engineered to uncover hidden defects, confirm structural integrity, and verify assembly quality across a wide range of applications.

At its core, Viscom helps their customers to ensure that their electronic assemblies are built correctly and free of defects. Modern electronics are extremely compact and complex. Components are smaller, boards are more densely packed, and assemblies often include hidden features. Viscom solves these challenges by offering industry-leading inspection systems that reveal both visible and hidden defects.

X-ray image revealing defects in electronic igniters. Credit: Viscom

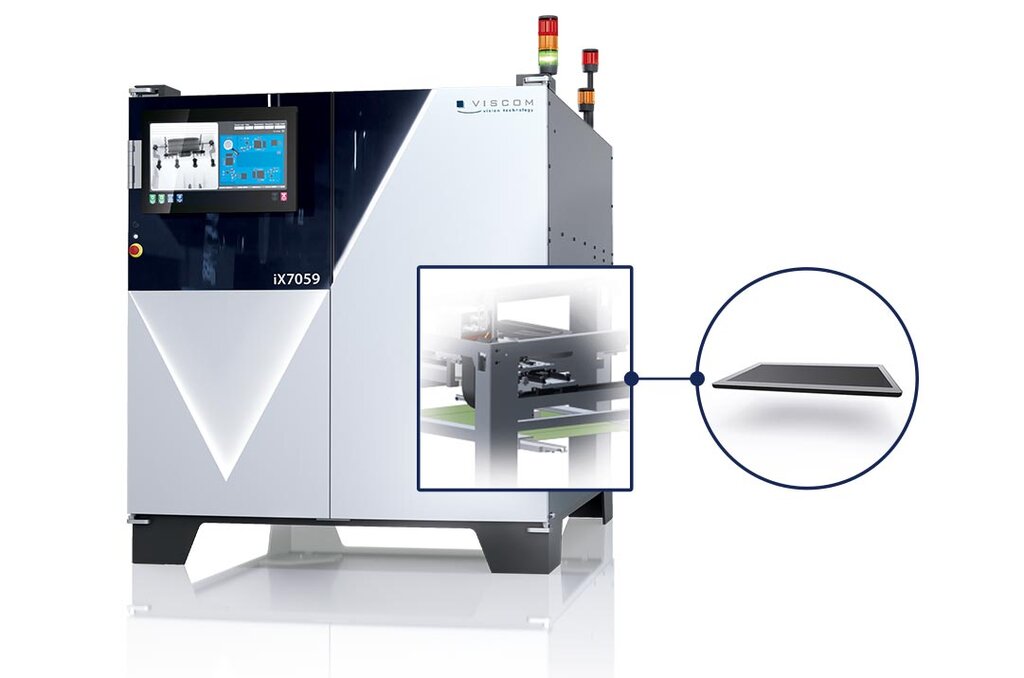

AOI technology focuses on optical inspection, identifying surface-level issues such as incorrect components, missing parts, or defective solder joints. AXI systems use X-ray technology to look inside assemblies and detect problems that cannot be seen from the outside, such as voids inside solder joints or hidden electrical connections. MXI tools give engineers hands-on control to explore complex assemblies with manual X-ray in detail, making them ideal for R&D, failure analysis, and specialized high-mix, low-volume production. With Viscom’s advanced X-ray technology, including the in-house development and manufacturing of our own X-ray tubes, we ensure that every step of the supply chain remains secure and uncompromised.

Viscom: Made in Germany. Trusted Worldwide.

Viscom’s heritage is rooted in German engineering, where precision, durability, and innovation are not optional, but expected. All our inspection systems are developed, manufactured, and rigorously validated in Hanover, Germany to maintain the highest possible quality standards. The materials are sourced mainly in Germany and the European Union. This commitment to excellence is why global OEMs, Tier-1 suppliers, and defense contractors trust Viscom.

Our inspection platforms combine advantage optics, high-performance imaging, intelligent algorithms, and robust mechanical design to deliver consistent, repeatable results under even the toughest conditions. From prototype evaluation to full-scale production, Viscom’s systems provide the actionable insights needed to guarantee product integrity at every stage of the lifecycle.

Viscom: Safeguarding Mission Success

In mission-critical sectors, inspection is more than a quality check, it is a safeguard against operational risk. At the core of Viscom’s mission is a commitment to ensuring that every electronic assembly meets the highest standards of quality, reliability, and durability. In defense and aerospace environments, electronic systems must withstand shock, vibration, extreme temperatures, electromagnetic interference, and years of uninterrupted service.

Failure is not an option, and Viscom’s technology helps ensure that every application, board, component, and connection is ready to perform under real-world conditions. The result is stronger mission readiness, greater equipment longevity, and reduced long-term risk.

Do you know what is inside your devices? We ensure the safety & integrity of your products. Credit: Viscom

Viscom’s global presence ensures that customers receive exceptional support wherever they operate. From initial consultation and system integration to training, optimization, and long-term service, our teams provide comprehensive assistance designed to maximize inspection accuracy and operational efficiency. Manufacturers rely on Viscom not only for advanced inspection hardware but also for the deep expertise and partnership required to sustain excellence across complex production lines.

Viscom: Shaping the Future of Mission-Critical Inspection

With headquarters and core production facilities located in Hanover, Germany, Viscom blends precision manufacturing with continuous innovation, offering solutions that meet the highest international standards. Viscom’s inspection systems are designed to provide absolute confidence in every layer, solder joint, and component, no matter how complex the assembly.

Example: Our inspection systems integrate seamlessly into existing inspection lines. Credit: Viscom

As technology continues to evolve and mission-critical electronics become even more sophisticated, the need for precise, reliable, and intelligent inspection systems grows. Viscom stands ready to support manufacturers and defense organizations with solutions engineered to reveal hidden defects, enhance product integrity, safeguard operational performance and secure supply chains. With a legacy rooted in German engineering and a future driven by innovation, like the newest AI solutions, Viscom remains committed to advancing inspection technology and ensuring that the systems protecting our world perform with absolute reliability.

Innovation at the Forefront

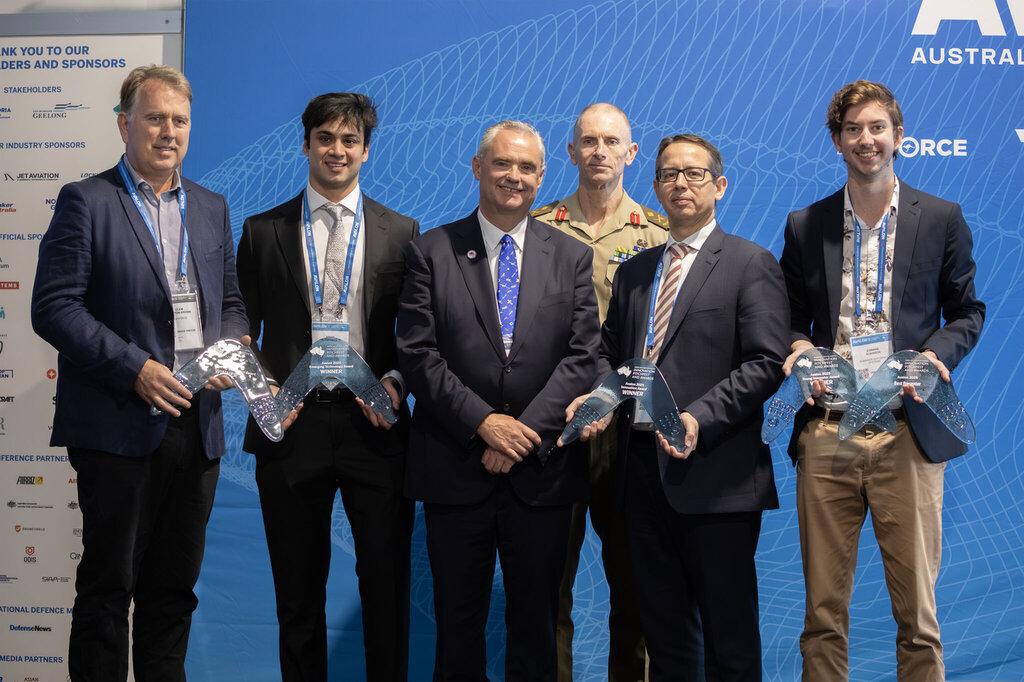

Avalon 2025 continued to serve as a launchpad for cutting-edge technology, with the Innovation Pitchfest and Awards providing a stage for breakthrough ideas. Judges praised the exceptionally high calibre of entries, with 23 finalists competing for prizes.

Four winners emerged, securing a combined $130,000 in funding to propel their innovations forward:

Avalon 2025 Innovation Award: Herve Aster, Neumann Space

Avalon 2025 Young Innovator Award: Edward Robinson, Robinson Aerospace

Avalon 2025 Emerging Technology Award: Nishq Ravindranath, Akula Tech Pty Ltd

Avalon 2025 Blue Sky Thinking Award: Clem Newton-Brown, Skyportz

Keynote speaker, Mike Henry. Credit: PDAC

Contact information

Viscom SE

Carl-Buderus-Straße 9-15

30455 Hanover

Germany

Tel: +49 511 94996-0

Email:info@viscom.com

Web: www.viscom.com

- Biffa internal savings data, average saving (January - August 2023)

- Nisbets internal savings data, average saving (January – September 2023)

- Compliance365 internal data, average savings

- HEINEKEN UK data, Calculations based on SmartDispense® active accounts each year since 2015 with 10 lines

- Independent test results based on subterranean and ground floor pub cellars of varying sizes

- Independent test results based on subterranean and ground floor pub cellars of varying sizes